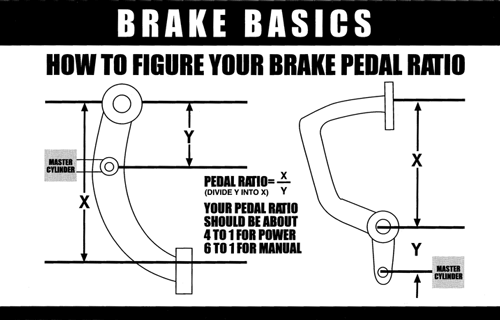

In other words if the distance from the brake pedal pivot to the center of the brake pedal is 8-inches the distance from the pivot to the master cylinder push rod should be about 2-inches. For power brakes the ratio should be 4 to 1. Additionally check your brake pedal ratio.

Power Brakes To Brakes Install My Cpp

Getting ready to install my cpp brake conversion kit on my 63 nova. Discussion Starter 1 Apr 29, 2013. An aggressive brake pad setup to have manual discs and lock up the tires.Auto Repair Library, Auto Parts, Accessories, Tools, Manuals & Books, Car BLOG, Links, Index8 Posts.

I have no clue when it comes to brakes.Required for power brakes (works w/ manual brakes too). Will the power booster even fit in the engine compartment. This car will be a cruiser not an everyday driver.

This may increase the distance it takes to stop the vehicle and create a potentially dangerous situation. Little old lady to bring two tons of Lincoln Town Car to a screeching halt with little more than a light caress of her foot against the brake pedal.Power brakes are great when they work correctly, but what happens when they don't? Suddenly it takes a lot more effort to bring the vehicle to a halt. So the magic of power brakes allows a 98 lb. Disc brakes are not "self-energizing" like drums brakes, so they require more pedal effort to apply.

As some famous scientist once said, "Nature abhors a vacuum." What he meant was as soon as you create a hole in the air (vacuum), the surrounding air tries to rush right in to fill it back up. The answer is the higher the vacuum, the greater the atmospheric push to fill the void. But to assist braking, it takes a lot of vacuum.How can something take a lot of nothing? After all, vacuum is the absence of atmospheric pressure. POWER BRAKE VACUUM BOOSTERMost power brake systems use a vacuum booster to assist braking.Vacuum is good for a lot of things, like sucking gas through a carburetor, opening and closing airflow doors in a vehicle's climate control system, and for providing extra muscle for braking.

Most engines pull a steady 16 to 20 inches of vacuum at idle. The average engine can't pull that much vacuum, so the most intake vacuum you're going to read is about 20 to 22 inches. Per square inch, which equals about 30 inches of vacuum on a gauge.

The booster housing is divided into two chambers by a flexible diaphragm. The original "Master-Vac" power brake booster that became the predecessor to virtually all vacuum boosters today was patented back in the 1950s by Bendix. So diesels have to use an auxiliary vacuum pump if they have a vacuum brake booster.How the brake booster uses vacuum to provide power assist is amazingly simple.

An 8-inch booster with 20 inches of engine vacuum will provide about 240 lbs. The larger the diaphragm, the greater the boost. The result is a forward push that helps shove the push rod into the master cylinder for power assist.The amount of power assist that's actually provided by the booster depends on two things: the size of the diaphragm and the amount of intake manifold vacuum produced by the engine. Suddenly, the diaphragm has vacuum pulling against one side and air pressure pushing on the other. This blocks off the vacuum port to the backside of the diaphragm and opens an atmospheric port that allows air to enter the back chamber. When the driver steps on the brake pedal, the input rod assembly in the booster moves forward.

Power Brakes To Brakes How To Check A

A low reading (below 16 inches) may indicate a hose leak or obstruction, a blockage in the exhaust system (plugged catalytic converter, crushed pipe, bad muffler, etc.), or a problem in the engine itself (manifold vacuum leak, bad valve, head gasket, etc.).The condition of the diaphragm inside the booster is also important. This happens because the blockage slows the return of vacuum in the booster.How To Check a Power Brake Vacuum BoosterTo check engine vacuum, connect a vacuum gauge to the supply hose that runs from the intake manifold to the booster. Consequently, the driver will have to push on the brake pedal harder to get the same braking as before.A restricted vacuum hose will cause boost to drop off when the brakes are applied in rapid succession. A vacuum supply hose that's loose, leaky, collapsed or restricted may not allow the booster to receive enough vacuum to provide the usual amount of power assist.

No change? Then check the vacuum hose connection and engine vacuum. You should feel the pedal depress slightly as engine vacuum enters the booster and pulls on the diaphragm. Then hold the pedal down and start the engine. Wetness around the back of the master cylinder would be another clue to this kind of problem.To check the vacuum booster, pump the brake pedal with the engine off until you've bled off all the vacuum from the unit. So if there's brake fluid inside the vacuum hose, it's a good indication the master cylinder is leaking and needs to be rebuilt or replaced. Leaks in the master cylinder can allow brake fluid to be siphoned into the booster, accelerating the demise of the diaphragm.

All you have to do is disconnect it from the brake pedal on the inside and unbolt the master cylinder. It should pass air from the rear but not from the front.Replacing a vacuum booster is a fairly straight forward job. You can check the valve by removing it and trying to blow through it from both sides. The valve also helps maintain vacuum when intake vacuum is low (when the engine is under load or is running at wide open throttle). This traps vacuum inside the booster so it can still provide one or two power assisted stops until the engine is restarted.

There's usually enough reserve pressure in the accumulator for 1 to 3 power assisted stops.Problems with this system can be caused by spool valve or piston wear inside the Hydro-Boost unit, fluid leaks or loss of pressure (worn pump, slipping pump belt, etc.).A simple way to test the Hydro-Boost system is to pump the brakes five or six times with the engine off to discharge the accumulator. The accumulator's job is to store pressure as an emergency backup in case pressure is lost (engine stalls or power steering pump drive belt breaks). This opens a valve port that routes power steering fluid into the cavity behind the piston to push it forward and apply the brakes.The Bendix Hydro-Boost unit fits between the firewall andThis eliminates the need for a vacuum booster.This setup is used on many older diesel engines (which produce no intake vacuum).Another component in the system is a pressure "accumulator." Some are nitrogen pressurized while others are spring loaded depending on the application. When the driver steps on the brake pedal, the pushrod slides forward and changes the position of the spool valve. The system uses hydraulic pressure generated by the power steering pump rather than engine vacuum to provide power assist.Inside the Hydro-Boost unit, which fits between the master cylinder and brake pedal the same as a vacuum booster, is a spool valve and piston assembly. Most require a small amount of play so the master cylinder will release fully preventing brake drag, but some late model GM and Bendix applications have zero play.Though not as common as vacuum booster power brake systems, the Bendix "Hydro-Boost" system dates back to 1973.

Grabby brakes are probably the result of contamination in the system or a broken spool return spring. You should get 2 or 3 soft brake applications before it takes more effort to push the pedal.Slow brake pedal return may be caused by excessive seal friction in the booster, faulty spool action or a restriction in the return line to the pump. Let the car sit for about an hour, then try the brakes without starting the engine. Like a vacuum booster, you should feel the pedal fall slightly when the engine starts, then rise.The leakdown of the accumulator can be checked by pumping the brakes several times while the engine is running, then shutting it off. Of force) and start the engine.

0 kommentar(er)

0 kommentar(er)